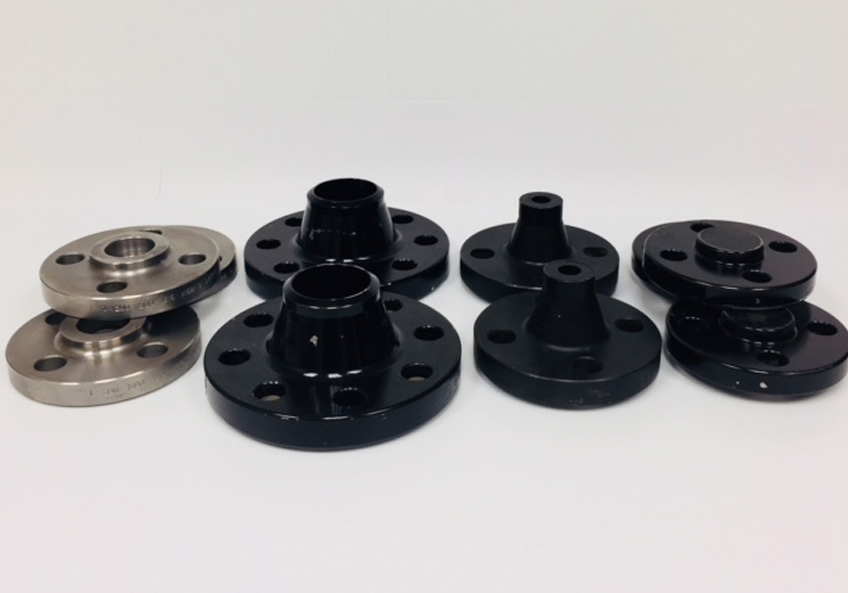

About This Product

Manufacturing Standards: ASME B16.9 – ASME B16.28 – ASME – B16.25

Information:

Fitting Types: 45°/90°/180° LR or SR Elbows, Concentric Reducers, Eccentric Reducers, Equal Tees, Reducing Tees, Caps.

Process: Seamless and Welded

Sizes: 1/2″ to 36″

Schedules: Sch10 up to XXS and heavier

Ends: Beveled or Plain

Availability: Stock and/or Production

Chrome Moly

WP5 / WP9 / WP11 / WP22 / WP91

Nickel Alloys

Alloy 59 / C276 / Alloy 20 / 400 / 600 / 625 / 800H / 825

Stainless Steel

304H / 316H / 317L / 310H / 321 / 410 / Duplex / 254 SMO

Urea grades

25.22.2 /UNS S 31050 / WP310 MoLN / 316L UG / 316LN UG

Titanium

Grade 2 / Grade 7

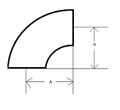

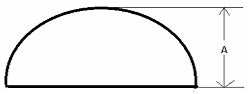

LR 90 Elbows

| Nominal Size | Dim A (inches) | Approximate Weight (lbs) | ||||||||||

| STD | Sch 40 | Sch 60 | XH | Sch 80 | Sch 100 | Sch 120 | Sch 140 | Sch 160 | XXH | |||

| 1/2″ | 1.5 | 0.1 | 0.1 | 0.3 | 0.3 | 0.6 | 0.7 | |||||

| 3/4″ | 1.5 | 0.2 | 0.2 | 0.3 | 0.3 | 0.6 | 0.7 | |||||

| 1″ | 1.5 | 0.4 | 0.4 | 0.5 | 0.5 | 0.6 | 0.8 | |||||

| 1-1/4″ | 1.88 | 0.6 | 0.6 | 0.8 | 0.8 | 1 | 1.4 | |||||

| 1-1/2″ | 2.25 | 0.8 | 0.8 | 1 | 1 | 1.8 | 2 | |||||

| 2″ | 3 | 1.6 | 1.6 | 2 | 2 | 3.2 | 3.9 | |||||

| 2-1/2″ | 3.75 | 2.9 | 2.9 | 4 | 4 | 6 | 6.8 | |||||

| 3″ | 4.5 | 4.6 | 4.6 | 6.3 | 6.3 | 10 | 11.3 | |||||

| 4″ | 6 | 8.7 | 8.7 | 12.5 | 12.5 | 15 | 22 | 23 | ||||

| 5″ | 7.5 | 14.4 | 14.4 | 20 | 20 | 28 | 33 | 38 | ||||

| 6″ | 9 | 24 | 24 | 33.5 | 33.5 | 44 | 62 | 69 | ||||

| 8″ | 12 | 46 | 46 | 58 | 70 | 70 | 85 | 103 | 116 | 122 | 120 | |

| 10″ | 15 | 86 | 86 | 109 | 109 | 130 | 164 | 201 | 232 | 270 | 232 | |

| 12″ | 18 | 120 | 129 | 180 | 160 | 210 | 269 | 315 | 365 | 460 | 315 | |

| 14″ | 21 | 156 | 170 | 270 | 191 | 310 | 371 | 415 | 490 | 563 | ||

| 16″ | 24 | 206 | 262 | 302 | 268 | 420 | 518 | 622 | 735 | 825 | ||

| 18″ | 27 | 256 | 369 | 512 | 318 | 620 | 747 | 872 | 1005 | 1130 | ||

| 20″ | 30 | 344 | 498 | 675 | 407 | 840 | 997 | 1178 | 1364 | 1518 | ||

| 24″ | 36 | 483 | 844 | 1170 | 632 | 1465 | 1730 | 2050 | 2310 | 2712 |

SR 90 Elbows

| Nominal Size | Dim A (inches) | Approximate Weight (lbs) | |||||||||

| STD | Sch 40 | Sch 60 | XH | Sch 80 | Sch 100 | Sch 120 | Sch 140 | Sch 160 | XXH | ||

| 1/2″ | |||||||||||

| 3/4″ | |||||||||||

| 1″ | 1 | 0.3 | 0.5 | 0.5 | 0.7 | 0.9 | |||||

| 1-1/4″ | 1.25 | 0.4 | 0.7 | 0.7 | |||||||

| 1-1/2″ | 1.5 | 0.5 | 0.8 | 0.8 | 1.1 | 1.4 | |||||

| 2″ | 2 | 0.9 | 1.5 | 1.5 | 2.4 | 2.8 | |||||

| 2-1/2″ | 2.5 | 1.8 | 2.3 | 2.3 | 3.5 | 4.9 | |||||

| 3″ | 3 | 3 | 3.8 | 3.8 | 5.6 | 7 | |||||

| 4″ | 4 | 6 | 7.8 | 7.8 | 10.2 | 12.5 | 14 | ||||

| 5″ | 5 | 9.5 | 13.5 | 13.5 | 17.7 | 23 | 26 | ||||

| 6″ | 6 | 15.5 | 22.5 | 22.5 | 29.6 | 36 | 57 | ||||

| 8″ | 8 | 31 | 41 | 46 | 46 | 57.8 | 69 | 77 | 81 | 80 | |

| 10″ | 10 | 55 | 71 | 71 | 86 | 109 | 126 | 151 | 173 | 158 | |

| 12″ | 12 | 78 | 86 | 118 | 100 | 145 | 179 | 210 | 235 | 283 | |

| 14″ | 14 | 104 | 118 | 159 | 132 | 210 | 247 | 295 | 345 | 387 | |

| 16″ | 16 | 118 | 160 | 225 | 160 | 312 | 325 | 431 | 526 | 577 | |

| 18″ | 18 | 148 | 227 | 310 | 194 | 397 | 507 | 610 | 720 | 810 | |

| 20″ | 20 | 210 | 332 | 449 | 280 | 575 | 672 | 795 | 960 | 1067 | |

| 24″ | 24 | 288 | 558 | 775 | 370 | 961 | 1147 | 1465 | 1731 | 1940 |

* Weights are approximate and for estimation purposes only. Weight may differ slightly for each manufacturer depending on the process of production.

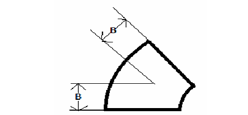

45 Elbows

| Nominal Size | Dim B (inches) | Approximate Weight (lbs) | |||||||||

| STD | Sch 40 | Sch 60 | XH | Sch 80 | Sch 100 | Sch 120 | Sch 140 | Sch 160 | XXH | ||

| 1/2″ | 0.63 | 0.05 | 0.05 | 0.15 | 0.15 | 0.3 | 0.35 | ||||

| 3/4″ | 0.75 | 0.1 | 0.1 | 0.15 | 0.15 | 0.3 | 0.35 | ||||

| 1″ | 0.88 | 0.2 | 0.2 | 0.25 | 0.25 | 0.3 | 0.4 | ||||

| 1-1/4″ | 1 | 0.3 | 0.3 | 0.4 | 0.4 | 0.5 | 0.7 | ||||

| 1-1/2″ | 1.12 | 0.4 | 0.4 | 0.5 | 0.5 | 0.9 | 1 | ||||

| 2″ | 1.38 | 0.8 | 0.8 | 1 | 1 | 1.6 | 1.95 | ||||

| 2-1/2″ | 1.75 | 1.45 | 1.45 | 2 | 2 | 3 | 3.4 | ||||

| 3″ | 2 | 2.3 | 2.3 | 3.15 | 3.15 | 5 | 5.65 | ||||

| 4″ | 2.5 | 4.35 | 4.35 | 6.25 | 6.25 | 7.5 | 11 | 11.5 | |||

| 5″ | 3.13 | 7.2 | 7.2 | 10 | 10 | 14 | 16.5 | 19 | |||

| 6″ | 3.75 | 12 | 12 | 16.75 | 16.75 | 22 | 31 | 34.5 | |||

| 8″ | 5 | 23 | 23 | 29 | 35 | 35 | 42.5 | 51.5 | 58 | 61 | 60 |

| 10″ | 6.25 | 43 | 43 | 54.5 | 54.5 | 65 | 82 | 100.5 | 116 | 135 | 116 |

| 12″ | 7.5 | 60 | 64.5 | 90 | 80 | 105 | 134.5 | 157.5 | 182.5 | 230 | 157.5 |

| 14″ | 8.75 | 78 | 85 | 135 | 95.5 | 155 | 185.5 | 207.5 | 245 | 281.5 | |

| 16″ | 10 | 103 | 131 | 151 | 134 | 210 | 259 | 311 | 367.5 | 412.5 | |

| 18″ | 11.25 | 128 | 184.5 | 256 | 159 | 310 | 373.5 | 436 | 502.5 | 565 | |

| 20″ | 12.5 | 172 | 249 | 337.5 | 203.5 | 420 | 498.5 | 589 | 682 | 759 | |

| 24″ | 15 | 241.5 | 422 | 585 | 316 | 732.5 | 865 | 1025 | 1155 | 1356 |

* Weights are approximate and for estimation purposes only. Weight may differ slightly for each manufacturer depending on the process of production.

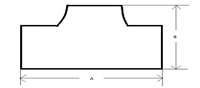

Tees

Weights are approximate and for estimation purposes only.

Weight may differ slightly for each manufacturer depending on the process of production.

| Nominal Size | Dim A (Inches) | Dim B (inches) | Approximate Weight (lbs) | |||||||||

| STD | Sch 40 | Sch 60 | XH | Sch 80 | Sch 100 | Sch 120 | Sch 140 | Sch 160 | XXH | |||

| 1/2″ | 2 | 1 | 0.3 | 0.3 | 0.3 | 0.3 | 0.6 | 0.8 | ||||

| 3/4″ | 2.26 | 1.13 | 0.4 | 0.4 | 0.5 | 0.5 | 0.7 | 1.2 | ||||

| 1″ | 3 | 1.5 | 0.9 | 0.9 | 1 | 1 | 1.1 | 1.5 | ||||

| 1-1/4″ | 3.78 | 1.883 | 1.6 | 1.6 | 2 | 2 | 2.1 | 2.3 | ||||

| 1-1/2″ | 4.5 | 2.25 | 2.1 | 2.1 | 2.8 | 2.8 | 3 | 3.5 | ||||

| 2″ | 5 | 2.5 | 3.3 | 3.3 | 3.9 | 3.9 | 4.5 | 5.5 | ||||

| 2-1/2″ | 6 | 3 | 5.9 | 5.9 | 6.7 | 6.7 | 7 | 10 | ||||

| 3″ | 6.78 | 3.38 | 7.6 | 7.6 | 9 | 9 | 12 | 14 | ||||

| 4″ | 8.28 | 4.13 | 12.2 | 12.2 | 16 | 16 | 20 | 22 | 25 | |||

| 5″ | 9.78 | 4.88 | 21.5 | 21.5 | 26 | 26 | 34 | 37 | 40 | |||

| 6″ | 11.28 | 5.63 | 34 | 34 | 44 | 44 | 54 | 63 | 66 | |||

| 8″ | 14 | 7 | 54 | 54 | 65 | 76 | 76 | 82 | 89 | 98 | 114 | 110 |

| 10″ | 17 | 8.5 | 88 | 88 | 110 | 110 | 163 | 187 | 218 | 246 | 265 | |

| 12″ | 20 | 10 | 126 | 139 | 187 | 165 | 210 | 318 | 361 | 412 | 389 | |

| 14″ | 22 | 11 | 159 | 195 | 279 | 225 | 335 | 402 | 445 | 510 | 561 | |

| 16″ | 24 | 12 | 220 | 265 | 312 | 265 | 452 | 536 | 618 | 704 | 768 | |

| 18″ | 27 | 13.5 | 295 | 360 | 490 | 358 | 650 | 788 | 864 | 995 | 1345 | |

| 20″ | 30 | 15 | 363 | 478 | 657 | 450 | 890 | 1005 | 1136 | 1310 | 1536 | |

| 24″ | 34 | 17 | 515 | 1080 | 1390 | 625 | 1525 | 1627 | 1856 | 2150 | 2600 |

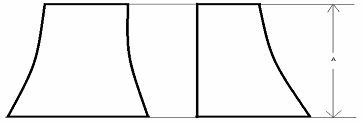

REDUCERS CONCENTRIC & ECCENTRIC

| Nominal Size 1 | Nominal Size 2 | Dim A (inches) | Approximate Weight (lbs) | |||||||||

| STD | Sch 40 | Sch 60 | XH | Sch 80 | Sch 100 | Sch 120 | Sch 140 | Sch 160 | XXH | |||

| 3/4″ | 1/2″ | 1.5 | 0.1 | 0.1 | 0.2 | 0.2 | 0.2 | 0.3 | ||||

| 1″ | 3/4″ | 2 | 0.2 | 0.2 | 0.3 | 0.3 | 0.4 | 0.5 | ||||

| 1/2″ | 2 | 0.2 | 0.2 | 0.3 | 0.3 | 0.3 | 0.4 | |||||

| 1-1/4″ | 1″ | 2 | 0.3 | 0.3 | 0.4 | 0.4 | 0.6 | 0.7 | ||||

| 3/4″ | 2 | 0.3 | 0.3 | 0.4 | 0.4 | 0.5 | 0.6 | |||||

| 1/2″ | 2 | 0.3 | 0.3 | 0.3 | 0.3 | 0.4 | 0.6 | |||||

| 1-1/2″ | 1-1/4″ | 2.5 | 0.5 | 0.5 | 0.7 | 0.7 | 0.9 | 1.2 | ||||

| 1″ | 2.5 | 0.5 | 0.5 | 0.6 | 0.6 | 0.8 | 0.9 | |||||

| 3/4″ | 2.5 | 0.4 | 0.4 | 0.5 | 0.5 | 0.7 | 0.8 | |||||

| 2″ | 1-1/2″ | 3 | 0.8 | 0.8 | 1.1 | 1.1 | 1.5 | 1.9 | ||||

| 1-1/4″ | 3 | 0.7 | 0.7 | 1.0 | 1.0 | 1.4 | 1.8 | |||||

| 1″ | 3 | 0.7 | 0.7 | 0.9 | 0.9 | 1.3 | 1.4 | |||||

| 3/4″ | 3 | 0.6 | 0.6 | 0.8 | 0.8 | 1.2 | 1.3 | |||||

| 2-1/2″ | 2″ | 3.5 | 1.4 | 1.4 | 1.9 | 1.9 | 2.6 | 3.3 | ||||

| 1-1/2″ | 3.5 | 1.2 | 1.2 | 1.6 | 1.6 | 2.2 | 2.9 | |||||

| 1-1/4″ | 3.5 | 1.2 | 1.2 | 1.6 | 1.6 | 2.0 | 2.8 | |||||

| 1″ | 3.5 | 1.1 | 1.1 | 1.4 | 1.4 | 1.9 | 2.4 | |||||

| 3″ | 2-1/2″ | 3.5 | 2.0 | 2.0 | 2.6 | 2.6 | 3.6 | 4.7 | ||||

| 2″ | 3.5 | 1.6 | 1.6 | 2.2 | 2.2 | 3.2 | 4.0 | |||||

| 1-1/2″ | 3.5 | 1.5 | 1.5 | 2.0 | 2.0 | 2.8 | 3.6 | |||||

| 1-1/4″ | 3.5 | 1.4 | 1.4 | 1.9 | 1.9 | 2.6 | 3.5 | |||||

| 4″ | 3″ | 4 | 3.1 | 3.1 | 4.2 | 4.2 | 6.1 | 7.7 | ||||

| 2-1/2″ | 4 | 2.8 | 2.8 | 3.8 | 3.8 | 5.4 | 6.9 | |||||

| 2″ | 4 | 2.4 | 2.4 | 3.3 | 3.3 | 5.0 | 6.1 | |||||

| 1-1/2″ | 4 | 2.3 | 2.3 | 3.1 | 3.1 | 4.6 | 5.7 | |||||

| 5″ | 4″ | 5 | 5.3 | 5.3 | 7.5 | 7.5 | 9.6 | 11.6 | 13.8 | |||

| 3″ | 5 | 4.6 | 4.6 | 6.5 | 6.5 | 9.9 | 11.9 | |||||

| 2-1/2″ | 5 | 4.3 | 4.3 | 5.9 | 5.9 | 9.0 | 10.9 | |||||

| 2″ | 5 | 3.8 | 3.8 | 5.4 | 5.4 | 8.4 | 9.9 | |||||

| 6″ | 5″ | 5.5 | 7.7 | 7.7 | 11.3 | 11.3 | 14.5 | 18.0 | 21.0 | |||

| 4″ | 5.5 | 6.8 | 6.8 | 10.0 | 10.0 | 12.7 | 15.6 | 18.5 | ||||

| 3″ | 5.5 | 6.1 | 6.1 | 8.9 | 8.9 | 13.7 | 16.5 | |||||

| 8″ | 6″ | 6 | 11.9 | 11.9 | 18.0 | 18.0 | 24.3 | 30.0 | 31.4 | |||

| 5″ | 6 | 10.8 | 10.8 | 16.1 | 16.1 | 22.0 | 26.9 | 27.8 | ||||

| 4″ | 6 | 9.8 | 9.8 | 14.6 | 14.6 | 19.9 | 24.3 | 25.0 | ||||

| 10″ | 8″ | 7 | 20.2 | 20.2 | 26.4 | 28.6 | 31.5 | 37.4 | 43.8 | 50.2 | 55.6 | 51.5 |

| 6″ | 7 | 17.4 | 17.4 | 24.3 | 27.2 | 36.7 | 47.0 | 45.9 | ||||

| 5″ | 7 | 16.1 | 16.1 | 22.0 | 24.9 | 34.0 | 43.4 | 41.7 | ||||

| 4″ | 7 | 15.0 | 15.0 | 20.4 | 23.2 | 31.6 | 40.3 | 38.4 | ||||

| 12″ | 10″ | 8 | 30.0 | 31.4 | 42.7 | 40.1 | 51.1 | 61.5 | 71.7 | 81.3 | 92.1 | |

| 8″ | 8 | 26.1 | 27.4 | 36.3 | 36.3 | 44.0 | 52.8 | 62.1 | 69.2 | 78.4 | ||

| 6″ | 8 | 22.9 | 24.2 | 31.4 | 39.1 | 54.0 | 68.6 | |||||

| 14″ | 12″ | 13 | 56.5 | 63.4 | 85.8 | 74.6 | 105.6 | 129.1 | 149.8 | 168.0 | 189.4 | |

| 10″ | 13 | 51.5 | 56.3 | 75.8 | 68.8 | 92.5 | 112.7 | 130.2 | 148.7 | 165.2 | ||

| 8″ | 13 | 45.1 | 49.9 | 65.4 | 62.6 | 81.1 | 98.6 | 114.7 | 129.0 | 143.0 | ||

| 16″ | 14″ | 14 | 68.4 | 85.4 | 112.4 | 90.4 | 141.7 | 172.6 | 200.4 | 230.0 | 253.6 | |

| 12″ | 14 | 65.5 | 79.6 | 105.5 | 86.5 | 131.5 | 158.9 | 185.6 | 212.1 | 236.8 | ||

| 10″ | 14 | 60.2 | 72.0 | 94.7 | 80.3 | 117.4 | 141.2 | 164.5 | 191.4 | 210.7 | ||

| 18″ | 16″ | 15 | 83.3 | 117.3 | 153.7 | 110.2 | 192.4 | 233.2 | 273.1 | 311.5 | 346.4 | |

| 14″ | 15 | 78.3 | 105.2 | 139.6 | 103.6 | 173.3 | 212.0 | 247.1 | 278.0 | 311.3 | ||

| 12″ | 15 | 75.2 | 99.0 | 132.2 | 99.4 | 162.4 | 197.2 | 231.2 | 258.9 | 293.3 | ||

| 20″ | 18″ | 20 | 124.4 | 190.0 | 254.1 | 164.8 | 316.8 | 387.1 | 450.9 | 513.2 | 573.6 | |

| 16″ | 20 | 117.8 | 171.7 | 228.5 | 155.9 | 288.2 | 351.1 | 407.7 | 471.1 | 520.8 | ||

| 14″ | 20 | 111.1 | 155.6 | 209.7 | 147.0 | 262.7 | 322.8 | 373.0 | 426.5 | 474.0 | ||

| 24″ | 20″ | 20 | 144.5 | 245.6 | 337.6 | 191.5 | 421.6 | 520.1 | 605.4 | 687.5 | 768.3 | |

| 18″ | 20 | 137.8 | 230.2 | 314.1 | 182.6 | 390.0 | 479.9 | 561.8 | 631.7 | 709.4 | ||

| 16″ | 20 | 131.1 | 211.9 | 288.5 | 173.7 | 361.3 | 443.9 | 518.7 | 589.5 | 656.6 |

* Weights are approximate and for estimation purposes only. Weight will differ slightly for each manufacturer depending on the process of production.

Caps

| Nominal Size | Dim A (inches) | Dim A (inches) | Approximate Weight (lbs) | |||||||||

| Thinner than XH | XH and heavier | STD | Sch 40 | Sch 60 | XH | Sch 80 | Sch 100 | Sch 120 | Sch 140 | Sch 160 | XXH | |

| 1/2″ | 1 | 1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.3 | 0.5 | ||||

| 3/4″ | 1 | 1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.3 | 0.7 | ||||

| 1″ | 1.5 | 1.5 | 0.2 | 0.2 | 0.3 | 0.3 | 0.4 | 1 | ||||

| 1-1/4″ | 1.5 | 1.5 | 0.3 | 0.3 | 0.4 | 0.4 | 0.5 | 1.5 | ||||

| 1-1/2″ | 1.5 | 1.5 | 0.4 | 0.4 | 0.5 | 0.5 | 0.6 | 2.5 | ||||

| 2″ | 1.5 | 1.75 | 0.6 | 0.6 | 0.8 | 0.8 | 1.3 | 3 | ||||

| 2-1/2″ | 1.5 | 2 | 0.9 | 0.9 | 1 | 1 | 1.8 | 4 | ||||

| 3″ | 2 | 2.5 | 1.5 | 1.5 | 1.8 | 1.8 | 2.9 | 6 | ||||

| 4″ | 2.5 | 3 | 2.5 | 2.5 | 3.3 | 3.3 | 6 | 6 | 9 | |||

| 5″ | 3 | 3.5 | 4.7 | 4.7 | 5.5 | 5.5 | 9 | 10 | 14 | |||

| 6″ | 3.5 | 4 | 6.5 | 6.5 | 10 | 10 | 13 | 15 | 18 | |||

| 8″ | 4 | 5 | 11.8 | 11.8 | 15 | 17 | 17 | 19 | 24 | 26 | 31 | 26 |

| 10″ | 5 | 6 | 22 | 22 | 27 | 27 | 30 | 34 | 46 | 53 | 57 | |

| 12″ | 6 | 7 | 30.6 | 35.5 | 44 | 38 | 62 | 74 | 82 | 90 | 95 | |

| 14″ | 6.5 | 7.5 | 37 | 43.5 | 55 | 47 | 75 | 102 | 146 | 179 | 200 | |

| 16″ | 7 | 8 | 40 | 53.5 | 75 | 55 | 86 | 133 | 187 | 229 | 297 | |

| 18″ | 8 | 9 | 54 | 117 | 154 | 72 | 190 | 254 | 317 | 423 | ||

| 20″ | 9 | 10 | 77 | 129 | 182 | 86 | 210 | 247 | 340 | 395 | ||

| 24″ | 10.5 | 12 | 86 | 208 | 285 | 129 | 337 | 485 | 562 | 697 |

* Weights are approximate and for estimation purposes only. Weight will differ slightly for each manufacturer depending on the process of production.

Recent Comments